|

Trackball.

An

Atari trackball as used in Centipede, Crystal

Castles, Missile Command etc.... is a roller ball enclosed in

a housing, that rolls on 3 roller pins which have bearings attatched

to their ends. 2 out of the 3 roller pins have have encoding wheels

located at one end of the roller, these wheels have small rectangular

holes (we'll call them windows) in them.

The encoding wheel when in situ rests in a slot in the optical coupler

so that it can freely spin. When the wheel is spun, it makes / breaks

the optical beam (i.e. ON/OFF) which creates

a pulse, which tells the game pcb how fast or slow and in which direction

it should move the game sprite.

Anyone who has had an Arkanoid or Tempest

set up, will already know this, as spinners use just one optical encoder

wheel and coupler. Because games like Crystal

Castles and Missile Command require

the sprite (i.e. Bently Bear or Target cross)

to move in all directions instead of just left and right, a trackball

uses 2 optical encoder wheels and couplers, 1 for Vertical (up/down)

and one for horizontal (left/right).

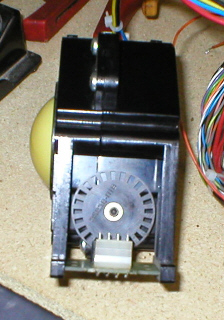

Pictured right is an Atari trackball from a Centipede game, this i am

going to use, so that i can convert Crystal castles

and Missile Command to Jamma and play them

in my 26" Jamma cab. This is how i have the trackball sat in front

of me, for co-ordination of layout, with the opto pcb's facing me, so

if i mention left hand side (arrow'd) or

right hand side, you understand where on the enclosure i am on about.

|

|

|

Optical

wheels and loom connectors.

Turning

the enclosure on its side (so that the right encoding

wheel is facing you)

you

will clearly see the wheel with its windows, in front of this, is a

molex type connector which has 4 pins, with the trackball in this position,

i number these pins from left to right : 1, 2,

3, 4 . So this is the Right hand connector and

the wiring for this is as follows :

Pin 1 = Horizontal

CLK

Pin 2 =5V+

Pin 3 =GND

Pin 4 = Horizontal

DIR

Now

turning the enclosure on its other side (so the

left encoding wheel is facing you) i again number these pins

from left to right : 1, 2, 3, 4 .

So this is the Left hand connector and the wiring for this is as follows

:

Pin 1

= Vertical CLK

Pin 2 =5V+

Pin 3 =GND

Pin 4 = Vertical

DIR

|

|

|

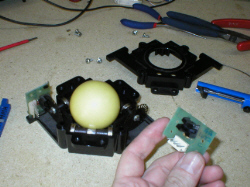

Dismantling

Trackball.

The Enclosure

itself comes in 2 halves, a top part and a bottom part. It is held together

with 6 phillips headed screws, simply undo these and the top part of

the enclosure can be lifted off. It is now possible to access all the

internal components. Here i have lifted out the left optical coupler/pcb.

N.B. In this pic i have turned the trackball assembly

around, so in my hand i have the left optical coupler/pcb and not the

right one which is still in situ...

|

|

|

Optical

coupler cleaning.

Once the optical

pcb has been lifted out it can be cleaned, 8 times out of 10 a non working

optical coupler is down to it being dirty, as dust and grime builds

up on the surface of the optic.

I found the best way to clean it, was to use a dry cotton bud and gently

rub it in the center slot of the optical coupler.

After that i gave the whole thing a good blast with my air duster can

( Maplins order code UP76H)

|

|

|

Bearings,

Rollers and lube.

The bearings and rollers are obviously what give the rollerball its

smooth action, so if yours is stiff, awkward to move or noisey, then

these need to be looked at and either lubricated or replaced. On the

bearings themselves i used regular 3 in 1 multi lube, so that they spin

nice and smoothly.

|

|

|

Bearings

and Rollers.

The rollers

themselves may have wear to the middle (where

the ball comes in contact) small wear of 1mm to 2mm is o.k. but

anything like the roller pictured (arrow shows

excess wear) should really be replaced with a new one. Trackball

kits are available from Arcadeshop

Amusements in the United states and are nicely priced at $20

for a complete kit of rollers and bearings or you can buy just the rollers

for $10. This is a very

wise investment as it makes your trackball run silky smooth once again.

|

|

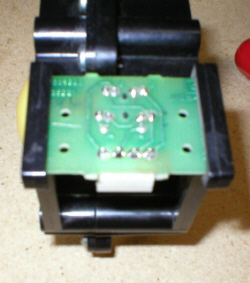

Soldered

joints.

On

the back of the optical pcb's are obviously the soldered joints, these

can have cracks or pits in them and not be making a proper circuit.

So it pays to reflow these with some fresh solder. Using a 15 to 18

watt soldering iron and a solder sucker or solder braid, remove the

old solder from one pin and then reflow in some fresh solder, do this

in turn to all the pins on the optical pcb.

Once you have done this to both of the optical pcb's, you are now

ready to try out your work by replacing it the game and using it.

If you still find after all this that the track ball still doesnt

work, you will need to replace either or both of the optical couplers.

|

|

![]()